Let’s move to the 3rd part of the nRF24 walk through series before the excitement cools off, shall we?

Now that I have three boards wired and I’m certain only my code can break things up, it is time to create the sensors’ firmware.

It should be quite simple: all we need to do is getting the transceiver set up at the beginning and send the current sensor identifier every time the button is pressed.

As this series is intended to be a tutorial, I’ll expand a little on the basic requirement. To add a bit of salt on our sensors’ network communication, we will expect the hub to send back to the nodes 2 pieces of information in response to their click events:

- the total count of clicks received from all nodes is going to be part of this article and we’ll achieve that using the ack packet payload

- the number of clicks received from the specific node will be instead added in another post, so not to push too much info in one shot

Each device is going to require a unique identifier: as radio network address (think ofit like an IP address) and for the software to print out (like a computer name). I will use one byte stored in EEPROM for both: this will limit the maximum amount of sensors for this network to 255 (0 is going to be reserved as the hub identifier/address).

That’s not such a low number after all, but we want our hub to print out the node identifier as a letter, so I will further limit the range to [1, 26] to simplify the hub code.

NOTE The above limits to the number of nodes is very soft and has been introduced into this tutorial to simplify the code. The real hard limit to the number of unique nodes is much higher and in the order of 1 thousand billions (

1followed by12zeros)!

Setting things up

The radio transceiver configuration occurs, as you might expect, in the setup() function, plus a global variable declaration and a few defines:

// Creates a new instance using SPI plus pins 9 and 10

RF24 radio(9, 10);

// nRF24 address family: all addresses will be in the format 0xFACEC0DE## with the last two

// bytes determined by the node identifier.

#define ADDR_FAMILY 0xFACEC0DE00LL

#define MAX_ID_VALUE 26

#define BUTTON_PIN 3

// This node unique identifier: 0 is used for the hub, anything above MAX_ID_VALUE is considered

// not valid

byte nodeId = 255;

void setup() {

SERIAL_DEBUG_SETUP(57600);

// Setup the push button

pinMode(BUTTON_PIN, INPUT_PULLUP);

// Read the address from EEPROM

byte reading = EEPROM.read(EEPROM_ADDR);

// If it is in a valid range for node addresses, it is our address

if (reading > 0 && reading <= MAX_ID_VALUE) {

nodeId = reading;

DEBUG("Node identifier is %c", nodeId + 64);

// Initialize the transceiver

radio.begin();

radio.setAutoAck(true); // Enables auto ack: this is true by default, but better to be explicit

radio.enableAckPayload(); // Enables payload in ack packets

radio.setRetries(1, 15); // Sets 15 retries, each every 0.5ms, useful with ack payload

radio.setPayloadSize(2); // Sets the payload size to 2 bytes

radio.setDataRate(RF24_2MBPS); // Sets fastest data rate, useful with ack payload

// Opens the first input pipe on this node address

radio.openReadingPipe(1, ADDR_FAMILY + nodeId);

// Opens the first input pipe on this node address

radio.openReadingPipe(2, ADDR_FAMILY + 254);

#if (SERIAL_DEBUG)

// Prints current configuration on serial

radio.printDetails();

#endif

} else {

DEBUG("Invalid node id %u found: use S## (a number between 1 and %u) to configure the board", reading, MAX_ID_VALUE);

}

}

There are a few details in the code related to the nRF24 module which might be valuable to explain:

- when I instantiate the module driver class I’m specifying only two out of the five pins used by module (not including the power line) because the

MISO,MOSIandSCKpins are defined by the boardSPIinterface - I’m defining a network address class

40bits long (0xFACEC0DE00), not very different from IP addressing when you specify the network class (192.168.0.0is the network classCof an host having IP address192.168.0.*) - I’m enabling auto acknowledge packets (useful to know if your transmission was successful) capable to carry payloads (more on this later)

- I’m instructing the library to auto retry packet transmission every half millisecond (

500 us) up to15times, so to reduce transmission errors - I’m setting a fixed payload size, which improves transmission reliability, of

2bytes - the data rate is set to highest possible value (

2Mbper second), so to have the ack packets coming back in time for being recognized (more on this in the next article) - one of the input pipes (the second if we count in pipe

0) is set to this node address. This is not used to receive ack packets (pipe0is used for that), but it will come into play later on, when I’ll show how the sensors can receive data (other than ack packets) from the hub (or whoever wants to talk to us, for what it matters!)

IMPORTANT Reading pipes are not associated to addresses you talk to, but to addresses you want to listen for. If that sounds confusing, consider reading pipes like mailboxes: you can have multiple mailboxes, but that does not limit who can send you mail, actually anybody knowing at least one of them can.

This means you are not limited to receive data from maximum five nodes (as commonly and mistakenly known) and this walk through will demonstrate it!

NOTE If you want to know more about pipes and addressing, the best source of information is the datasheet, but to summarize:

- you have one writing pipe only, but you can change it’s value to whatever address you want to talk to

- there are six reading pipes, only two (

0and1) can be associated with40bits addresses, with pipe0automatically associated to the writing address (to receive acks); this means pipes1to5share the same upper32bits, but you can change the reading pipes addresses- almost every address is valid, only a few are excluded (like

0x0000000000,0xFFFFFFFFFFand similar)- address length is configurable to

40(default),32or24bits, but the limitation on pipes1to5still applies as they keep sharing the upper24or16bits

For the sensors’ setup() function to complete correctly we need to read a valid node id from EEPROM which means we have to push something in the correct location: this is responsibility of another function called config(). I’m not going to analyze that function in detail, but it should be clear its purpose is to allow to set the node id using a serial connection.

A looping life

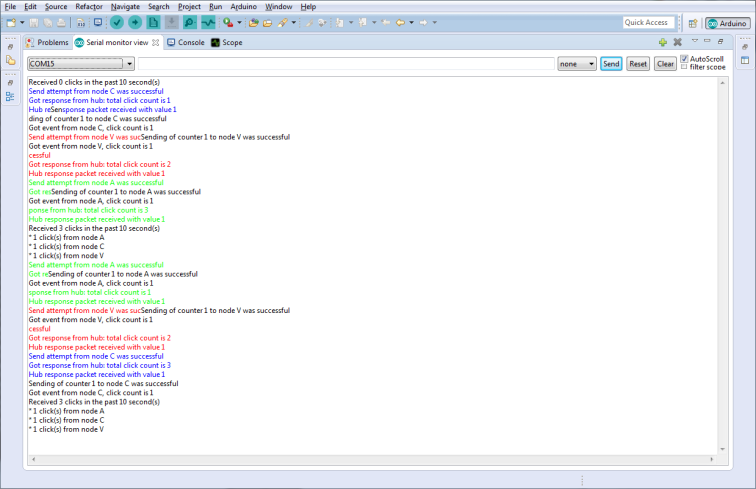

Moving into the sensor loop() function, the plan is even easier, if possible: check the button state and, if pressed, send the sensor node identifier to the hub.

To add value to this tutorial we will expect the hub to send back the total amount of received clicks and we will use ack packet as the carrier of this information.

NOTE Acknowledge (here abbreviated into ack) packets are used to verify data transmission has been successful. This is a common technique used in TCP/IP protocol as well: if you don’t feel comfortable with the concept just consider those as return receipts.

The protocol used by this chip allows to optionally attach some information to the return receipts: we refer to this info as the ack packet payload.

Ack packets maximum payload size depends on data rate and re-transmission speed and is explained in details in the nRF24 datasheet at paragraph 7.5.2.

I’m going to use some macros to perform a simple software debouncing on the push button, but apart from that, the code should be very easy to read:

// Button debouncing macros

#define DEBOUNCE 15

#define DMASK ((uint16_t)(1<<DEBOUNCE)-1)

#define DF (1<<(uint16_t)(DEBOUNCE-1))

// Macro for detection of falling edge and debouncing

#define DFE(signal, state) ((state=((state<<1)|(signal&1))&DMASK)==DF)

// Button debouncing status store

unsigned int buttonStatus;

void loop() {

// Checks if we are trying to configure the node identifier

config();

delay(1); // Slow down a bit the MCU

// Checks the push button: if we enter here the button has been pressed

if (DFE(digitalRead(BUTTON_PIN), buttonStatus)) {

// Sets the destination address for transmitted packets to the hub address

radio.openWritingPipe(ADDR_FAMILY);

// Put transceiver in transmit mode

radio.stopListening();

// Transmit this node id to the hub

bool write = radio.write(&nodeId, 1);

DEBUG("Send attempt from node %c was %s", nodeId + 64, write ? "successful" : "UNSUCCESSFUL");

// Get acknowledge packet payload from the hub

while (write && radio.available()) {

unsigned int count;

radio.read(&count, 2);

// This function shows how a node can receive data from the hub

// without using ack packets payload

receiveNodeCount();

DEBUG("Got response from hub: total click count is %u", count);

}

}

}

Once again, let’s analyze in detail the parts specific to the nRF24 module, which are activated whenever the push button state has gone LOW for enough time:

- I set the transmission destination address using the

openWritingPipe()function, providing the hub node identifier (that is the node we want to send data to) - to put the module into transmit mode we need to call the

stopListening()function - since ack packets have been enabled, we can transmit reliably, so the result of the

write()function (a boolean value) is going to be stored and checked - the data I’m going to transmit (the sensor node identifier, stored into the

nodeIdglobal variable) is provided to thewrite()function along with the number of bytes (only one) we are going to send. The actual payload sent on the air is going to be2bytes long, because we have set the packet size to a fixed value of2, which means the packet will be zero filled - if the transmission was successful we expect to have an ack packet available. We have enabled ack packets payload, so we can pull out an

unsigned int(2bytes) into thecountvariable: this represents the total amount of clicks the hub has received so far

This is a complete example of data exchange, but the fact we are using the ack packet payload has some caveats we will analyze when we will talk about the hub.

The whole picture

The complete sensor’s firmware is available on Github and its compilation requires the two libraries mentioned in the previous post: the RF24 lib from TMRh20 and my own MicroDebug lib.

Please ignore the receiveNodeCount() function call and its implementation for now: we’ll get into that in another post. If you prefer, comment out line 105 to completely exclude that part of the firmware.

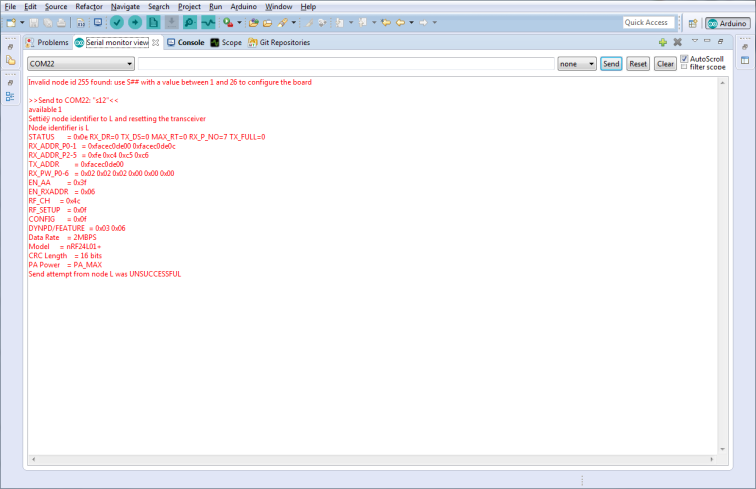

Naming the newborns

To avoid packet transmission conflicts we will have to initialize each sensor board with its own unique identifier: that’s the part handled into the config() function.

Internally I will use numeric identifiers, but they will be translated into one character when printing, hence the limit to numerical values between 1 and 26: that’s the number of letters in the latin charset.

Each board will initially have 255 as identifier, which is to be considered invalid, but you can change it via serial.

Once connected, type the S character followed by the board identifier you want to assign (like S2 or s5): the board will print the corresponding identifier as a character, store it in EEPROM and self reconfigure.

IMPORTANT The communication relies entirely on assigned node identifiers. The hub has no other way than the node identifier to distinguish between the nodes.

If you configure two nodes with the same identifier they will be considered as one and their clicks will not be distinguished. You can leverage this in some situations and have two sensors appear as one, if that’s what you want.

Repeat the procedure on each board and you have your sensors setup!

From this point forward your sensors does not require to be hooked up to your computer, they will just need power. If you have enough USB ports available and decide to leave the sensors connected to your computer though, you will be able to receive some debug messages on the serial ports and enjoy the occurring communication… once we have the hub running!

Very nice walkthrough which actually worked and gave me a reliable setup. I was wondering at the end of this part how to then have ‘the HUB” configured, re-read the whole article and first wondered if it was adress0 to be configured for the HUB but then realized it actually required dedicated HUB code located in your Github in a seperate folder, might want to clarify that for others 🙂 THANKS again for the nice walkthrough !!

LikeLike

Other articles are on their way, I had a stop in order to verify the amount of nodes one hub is capable to sustain reliably so I’m building more nodes to run a test. I’ll be back to writing once I’ve a better figure.

LikeLike

can you also incorporate controlling relays in one of these walk through posts? These posts seem to lay the ground very well on the subjects. Do you have a suggested reading list on nRF24L01?

LikeLike

Relay control should be quite easy from a software standing point, with or without an nRF24 module in the middle… Turn the correct pin HIGH or LOW to drive the relay. The challenge is in the voltage difference and opto isolation, if desired….

With regards to the reading list my path was the original RF24 GitHub pages and its author’s blog, followed by the datasheet and the new fork GitHub pages…

LikeLike

i guessing with Arduino most of the Relay Module’s are opto isolated?. I’m trying to control the electric blinds at home with Arduino and jumped into nrf24 at the final moment without realizing it would be the bigger part of the code. Thank you for these guides and the code, they help a great deal.

LikeLike

Also, I to avoid any confusion this line

/* THE FOLLOWING LINE IS NEEDED FOR ARDUINO BASED ON 32u4 CHIPS LIKE LEONARDO AND MICRO */

// while(!Serial.available()) delay(100);

causes communication problems in Arduino Nano. Once I removed it everything worked fine.

LikeLike

Which USB to Serial does your Nano use? It might be related to a specific one, because I actually have a couple of Nano running that code without any issue… And can you describe the difficulties you experienced as well, please?

LikeLike

Careful with the cheap arduino relay boards!! They do have an optoisolator but then use the same power supply on the secondary site! Some of them you can change with jumpers to a more sane setup: https://arduino-info.wikispaces.com/RelayIsolation

LikeLike

btw I had to search for the HUB code as well. You might want to mention that its here since I jumped into trying the code with the github link. Thank you for this it works great. https://raw.githubusercontent.com/rlogiacco/nRF24-Walk-Through/master/hub/arduino/hub.ino

LikeLike

That code is not finished yet: the walk through is still missing a few posts, I’ve been really busy at work recently…

LikeLike

Very nice write-up! I’m planning a setup as you sketched in your introductory article (Particle core as hub, with nano’s as nodes).

Hope my comment will give you a boost to keep on writing; looking forward to the next part in this series!

LikeLike

Great post! I do not have nano’s. Is it possible to use Particle core as hub and nodes? I do have only multiple photons. Thanks again.

LikeLike

What would be the benefit of using nRF24 with boards already hosting a WiFi transceiver? Obviously unless you it for study/research reasons only, in which case the answer is “yes, you can, with a few code adaptation due the fact the code for the nodes is developed with Arduino in mind”.

LikeLike